[ad_1]

Ember’s first Indiegogo campaign drew sideways glances when it launched in 2015. Would anyone actually buy a $129 heated coffee mug? Nearly a decade later, however, it’s clear that the initial pitch was merely the tip of the startup’s heating/cooling iceberg.

TechCrunch recently sat down with Clay Alexander, the firm’s founder and chairman, to take a deep dive into Ember’s history — and catch a glimpse of where things are headed.

“We’re well over 3 million units [of the smart mug] at this point,” the executive tells TechCrunch. “We’re nearing a million units a year now. When I first created this technology, I had so many people in my life say, ‘oh Clay, you’ll never sell a $100 electronic coffee mug. You’ve lost your mind.’ As a founder, you just have to have perseverance, and you have to have this gut instinct that overpowers logic.”

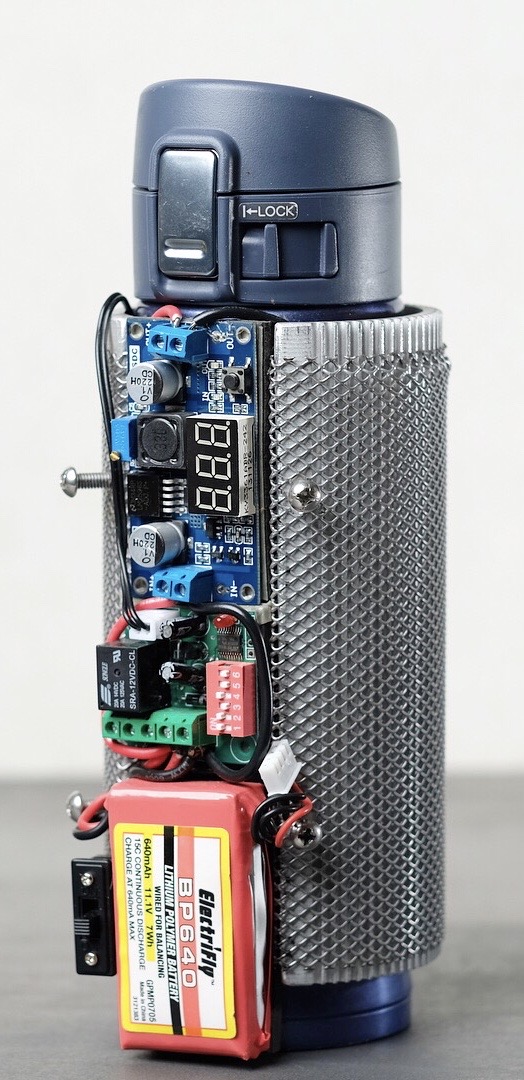

The first prototype of the Ember mug was a Frankensteinian prototype involving a Zojirushi mug and a bunch of electronics. Image Credits: Ember

Beyond the company’s better-known coffee receptacle, Ember has made a foray into the medical sector with the Ember Cube, a shipping box for things that need to stay temperature-controlled — primarily medicines. It also makes heated baby bottles now, too.

“I always say to people that cooling is much harder than heating. Heating is fairly straightforward in that you can create a heater by using a resistive heating element or a resistive heating wire. I mean, heck, you can just put electricity and any wire. It’s gonna warm up, right?,” Alexander notes. Cooling is a different beast, however. “People don’t realize that you’re not pumping cold energy into a fridge — you’re actually pulling heat energy out of the box.”

Beginnings

Ember’s inception can be traced back to a relatable moment of frustration: a lukewarm cup of coffee. Alexander, a self-proclaimed coffee aficionado, longed for a solution to maintain the perfect temperature of his favorite brew from the first sip to the last. The path to bringing Ember to life was challenging. As a hardware startup, Ember faced unique obstacles that often deter entrepreneurs from venturing into this space. From the high product development and manufacturing costs to the complex web of IP protection and international expansion, Alexander navigated a maze of challenges that would test his resolve and determination.

Despite obstacles, Alexander remained steadfast. He assembled a team of engineers, designers and marketers who shared his passion for creating a product that would enhance the coffee-drinking experience and push the boundaries of what was possible in consumer technology. As Ember began to take shape, Alexander and his team poured countless hours into research and development, testing various materials and technologies until they arrived at a solution that met their bar. The result was a sleek, intuitive mug that could maintain a precise temperature for hours, controlled through a simple smartphone app. Indeed, 2,000 backers rallied to the idea on Indiegogo, giving the company a $360,000 cash injection and its first hint at market validation. Not long after, the company raised a series of equity rounds, including a $13 million Series C and a $23 million Series E.

Balancing form and function was an early challenge familiar to anyone in the hardware space. The mug needed to effectively maintain temperature while also being visually appealing and comfortable to hold. After extensive testing and refinement, Ember eventually settled on a sleek, minimalist design that seamlessly integrated the heating technology into the mug’s walls. The mug also features wireless charging, customizable temperature settings and a smartphone app that allows users to control it remotely.

Then there’s the challenge of actually bringing the product to market. Unlike software development, hardware development requires significant upfront investment in materials, tooling and manufacturing processes. As Alexander notes, these costs can quickly balloon, putting immense pressure on startups to secure funding and generate revenue as soon as possible.

Across the sea

Once a product is developed, hardware startups must navigate the complex world of intellectual property protection. In a fiercely competitive market, safeguarding one’s innovations is critical to long-term success, but securing patents and trademarks can be time-consuming and expensive. This can be a daunting prospect for startups with limited resources, requiring careful strategizing and prioritization.

At one point, Ember found an incredible opportunity, which turned out to be a considerable challenge. Until this point, the mugs were already on sale in Starbucks and in other high-profile retail stores. But then, one of the biggest and most influential retailers in the world came knocking.

“We were expanding not just in the U.S. It took us about two years to get into the Apple store — the amount of testing they put your product through is wild — and the number of times I flew up to Cupertino… but it was worth it,” Alexander remembers. “But Apple does not like to do localized launches. If they like your product, and you’ve passed all their tests, they basically come to you and say, Okay, we want to do this on a global scale.”

At the time, Ember was only shipping to North America, but when Apple came knocking and said it wanted to start selling its product in 27 countries, they didn’t ask whether to jump, but rather how high to hop.

A Portable Medicine Cooler Prototype created in collaboration with the Mayo Clinic in 2018. Image Credits: Ember

“I remember going to my ops team and saying, ‘Guys, Apple’s coming to us with a silver platter, which would turn us into an international brand overnight. Are we going to do this?’ And it was a couple of weeks of whiteboarding and blind panic,” Alexander laughs. “And ultimately, we just said, ‘You know what, you only live once, let’s do this,’ and it was the most excruciating year of our lives. We went from North America to 27 countries with Apple.”

As Ember began to expand internationally, Alexander and his team encountered challenges around navigating the regulatory landscapes of different countries, securing reliable manufacturing partners and adapting to local market conditions. Each challenge required a deep understanding of the global hardware ecosystem. Alexander credits Ember’s success in this area to the strength of his team and their willingness to learn and adapt on the fly.

Going from hot to cold

While Ember’s smart mug has been a resounding success in the consumer market, the company’s ambitions extend far beyond hot beverages.

A prototype of a cylindrical medicine cooler was developed in collaboration with the Mayo Clinic. This concept was from 2019. Image Credits: Ember

I love selling coffee cups, don’t get me wrong, but being able to save lives has been something that all of us can rally behind. Clay Alexander

“I remember thinking, ‘What can we do with our temperature-control technology to help save lives?’ I could see that we were becoming very successful in consumer,” Alexander explains. “I had Wyatt Decker, the CEO of the Mayo Clinic in Arizona, on my board of directors. It was really cool to have a big-time healthcare executive on our board. And he would invite us out to the Mayo Clinic. And we would sit there in these conference rooms with doctors and scientists. Our idea was to unearth how our temperature-control technology could help solve pain points in healthcare, whether it’s medicine or moving organs around or what-have-you.”

Alexander and his team retreated back to the lab to start tackling the challenges it had discovered, putting its dozens and dozens of patents to good use. The company says it has more than 200 granted patents today, almost all of them in temperature control, whether it’s semiconductor refrigeration technologies, heating technologies or the control systems to manage it all.

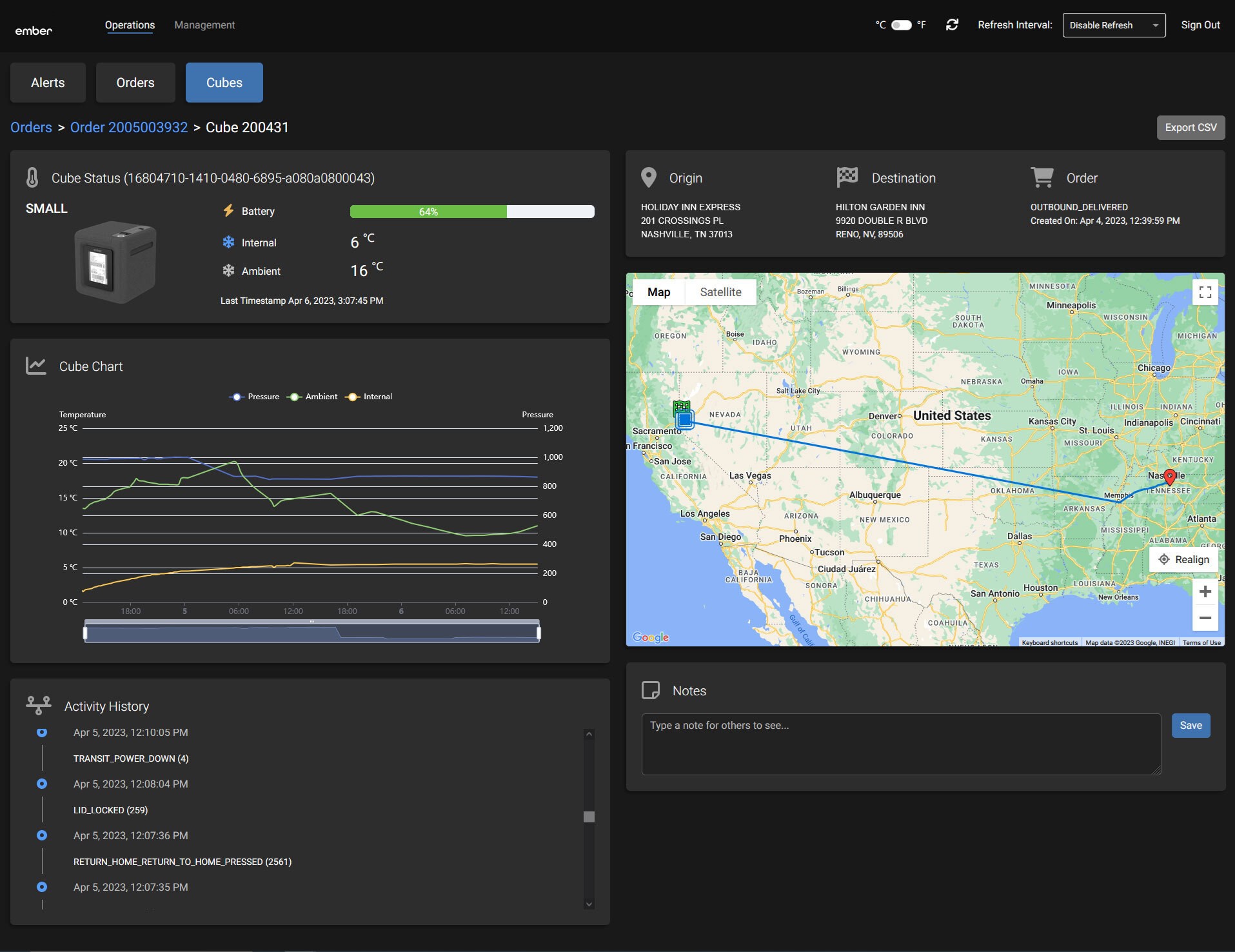

The work gave rise to Ember Cube, a device that promises to solve one of the most pressing challenges in the medical field. Many medications, particularly those used in cancer treatment and vaccine distribution, require precise temperature control to maintain efficacy. Even slight deviations from the optimal temperature range can render these medications useless or harmful. The Ember Cube addresses this issue by providing a portable, highly accurate, temperature-controlled environment for storing and transporting sensitive medications. Leveraging the same ethos used in its intelligent mugs, the Ember Cube maintains a precise temperature range, ensuring that the medicines inside remain viable and effective.

The Ember Cube dashboard enables shippers to see the medicines in transit in near-real-time, complete with temperature readouts. Image Credits: Ember

If properly executed, the technology could be a game changer. By enabling the safe and efficient distribution of temperature-sensitive medications, the Ember Cube could help to improve access to life-saving treatments in remote or underserved areas. It could also reduce the cost and complexity of vaccine distribution, a critical consideration in the face of global health crises like the COVID-19 pandemic. Once you have the technology, tons of opportunities start to surface. For example, the U.S. Anti-Doping Agency revealed that it uses Ember’s technology ahead of the 2024 Olympic team trials.

Alexander notes that he sees the development of the Ember Cube as a natural evolution of Ember’s mission to use technology to solve real-world problems. By applying its expertise in temperature control to the medical field, Ember is poised to make a meaningful difference in the lives of patients worldwide.

Spinning out

The decision to split Ember into two distinct divisions — consumer and life sciences — was a strategic move designed to allow each arm of the company to focus on its core competencies and target markets. By creating a dedicated life sciences division, Ember can channel its resources and talent toward developing new applications for its technology in the medical field, from improving the storage and transportation of vaccines to enabling more precise temperature control in laboratory settings.

The split enables the company to serve different customer populations — both in the product sense and in the investor sense — and the company hired a former Dyson exec (Jim Rowan) as the CEO of its consumer division.

“About a year and a half ago, we actually spun out Ember Life Sciences as a standalone entity,” Alexander says. The company initially kept the same cap table for both companies but allowed the two entities to diverge from there. “It allowed us to raise capital from the healthcare industry, and we’re quite proud of some of our equity partners. Carrier — the world’s largest commercial refrigeration manufacturer — is our investor. We also have some other investors as well in the healthcare space. By spinning it out, we could attract life sciences and healthcare type of equity investments and board members, etc., as opposed to when we had them all combined.”

From cool to very cold indeed

“We’re actually trying to move into the cell and gene therapy space with cryogenic shipping,” Alexander teases, showing me a photo of the prototype device. He then swears me to secrecy, saying I can’t share the picture I’ve seen.

As Alexander looks to the future, he is filled with excitement and possibility.

The Ember Cube can keep products at 5degC (41F) for 72 hours. The company’s next foray is cryogenic shipping, in which the temperature must stay at -150C (-238F) for extended periods.

“Negative 150C is no joke. It’s a hell of a thing. We use liquid nitrogen, and the shipping box has a sponge-like material, so the nitrogen gets absorbed into the walls. If it gets tipped over, nothing comes out, it’s a dry shipper,” Alexander says. “It’s a major engineering challenge. You have to do it in a vacuum, and it’s all very complex engineering.”

Alexander says the cryogenic shipper is around 18 months from being available as a commercial product, but the Ember team is psyched about the progress it has made so far.

“We’ve run thermal chamber testing and have been able to keep the payload below negative 150 Celsius for 10 days,” Alexander explains. “The target audience for this is cell and gene therapy — super high-tech medicine that is literally curing cancer and saving lives. Talk about a feel-good thing as a brand, right? I love selling coffee cups, don’t get me wrong, but being able to save lives has been something that all of us can rally behind.”

[ad_2]

Source link